How much do structural insulated panels (SIPs) cost? And, perhaps not surprisingly, it’s a difficult question to answer because each project is so unique.

A simple rectangular cabin would be far less complicated than, for example, a home with complicated roof lines with various pitches. Other variables include the thickness of panel required, the site, which walls will be SIPs, snow load requirements and other building codes. Each of these variables factor in to the total cost of the panels.

Pricing information can be obtained by contacting any SIPs manufacturer. Like most other products, there are low and high-end versions of SIPs, so it’s important you are making apples-to-apples comparisons when shopping. A blank panel with no customization will cost much less than one which is highly-customized and completely factory-finished.

Speaking in general terms, industry wide, a blank six-inch wall panel will cost somewhere between $5 to 8 (2018 pricing) per

square foot of panel.

Or, you can look at it from the amount of living space created within the SIPs building envelope: a basic design would run about $17 to 30 (2018 pricing) per square foot for the exterior shell, including wall and roof panels.

Sticker shock? Perhaps. Material expenditure may be a bit higher with SIPs than with conventional wood construction. But, it’s important to realize that’s only one part of the equation.

Let’s look at it from a different angle: What will using SIPs save, both short and long-term?

Labor

The material price doesn’t account for the labor savings afforded with SIPs construction. According to a study conducted by RS Means, building with SIPs can decrease framing labor by as much as 55% over conventional construction. Such a significant impact to overall cost ought not be overlooked when tallying up construction costs.

Time

While it does take time to unload and stage the panels, the ease with which they fit together is a less laborious and time-consuming matter than stick-framing a structure. Overall studies show an approximate 50% decrease in onsite construction time.

Faster dry-in means subcontractors can begin work on the interior sooner — and in a climate-controlled, more comfortable environment. A quick construction time frame also means the structure can be ready for occupancy in a more timely fashion as well.

Waste

A 2012 study by Aaron Seward, published in Architect 101, points out that conventional construction accounts for 40% of the waste in landfills. Further, SIPs “nearly eliminate onsite waste due to framing, up to a 98% decrease. Builders can expect fewer costs associated with waste disposal when using SIPs.

Energy consumption

This is perhaps the most beneficial aspect of SIPs, both long and short-term, when it comes to dollars and cents. According to Seward:

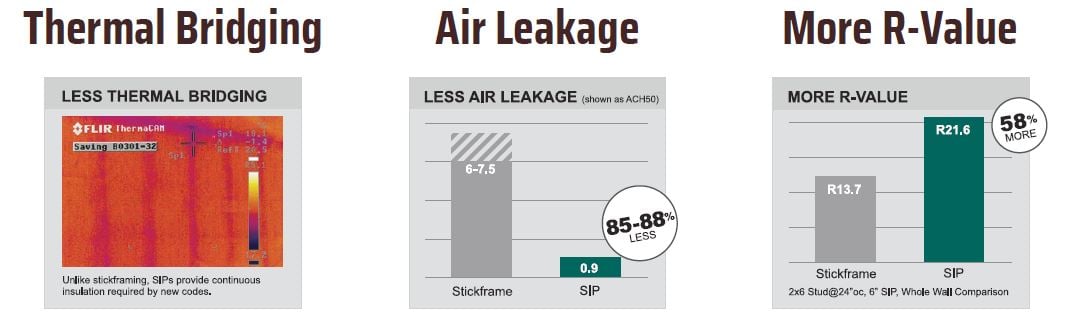

Although life cycle costs were not part of this study, it should be noted that SIPs installed to meet Energy Star requirements offer significant savings in energy use. A typical 2’ x 6’ wall with fiberglass batt insulation has an R value of 19 while the comparable SIPs wall is rated at R 22.3. In addition to the higher R values, the sealed joints between the SIPs reduce air leakage (drafts) and energy loss. Energy efficiency is a very attractive selling point with many potential buyers, despite the higher material costs of SIPs, because they minimize heat loss/gain in a new home, increase comfort, and save money in the long run.

Building owners can also expect substantial savings on HVAC equipment as smaller, less expensive units are used for heating and cooling; further, smaller equipment costs less to operate.

Building owners can also expect substantial savings on HVAC equipment as smaller, less expensive units are used for heating and cooling; further, smaller equipment costs less to operate.

So, how much do SIPs cost? While the initial materials cost may be slightly higher than conventional building materials, when you look at the rest of the factors contributing to construction costs — reduced labor expenses, heightened site productivity, decreased waste and less overall energy consumption — the sum total makes sense. When all the factors are considered, building with SIPs is virtually the same or even less expensive than other building systems.