Not all insulation is equal

In the world of building construction, we often talk about R-value and assign it a specific number associated with a building’s insulation. But home energy raters know that not all insulation is created equal.

When the R-value rule was instituted, most homes and buildings were constructed using 2-by-4 lumber and fiberglass insulation. To increase a home's insulation, a builder would have selected a fiberglass insulation product that had a higher R-value. Today we know it is not the R-value of the insulation that makes the wall more efficient – it’s a combination of insulation materials, construction details, and installation care that provide ultimate thermal performance.

EPS (Expanded Polystyrene) insulation improves as the air outside gets coldEnercept structural insulated panels (SIPs) are made with expanded polystyrene (EPS) like the foam  you see in disposable coffee cups and beer coolers. Its nominal R-value is 4 per inch and the main type of rigid foam board we use in our roof and wall sheathing. Additionally, ESP insulation’s R-value improves as the outdoor temperature turns cold. Today’s modern high-tech engineered EPS insulation may be the best rigid insulation in many aspects. One aspect is that EPS has a very good and stable R-value. In fact, when temperatures are colder, EPS’s R-value actually increases by over eight percent.

you see in disposable coffee cups and beer coolers. Its nominal R-value is 4 per inch and the main type of rigid foam board we use in our roof and wall sheathing. Additionally, ESP insulation’s R-value improves as the outdoor temperature turns cold. Today’s modern high-tech engineered EPS insulation may be the best rigid insulation in many aspects. One aspect is that EPS has a very good and stable R-value. In fact, when temperatures are colder, EPS’s R-value actually increases by over eight percent.

R-value is the measure of the thermal resistance of a material or component. Typically, when fiberglass insulation is marked “R-13” or “R-19”, that R-value was tested in conditions where the mean temperature was 75 degrees. Fiberglass batt insulation gets its R-value through trapped air, which means when the temperature drops, so do the R-values. The American Society of Test Methods (ASTM) specifies the ways that manufacturers must test the ability of the insulating material to resist heat transfer. ASTM requires the laboratory to test the products by changing the temperature so that the outside exposure is 50 degrees different than the insulated space. Testing equipment measures how long it takes for the insulated space to gain or lose temperature.

Critics, however, state that these testing conditions don't reflect reality. The outside temperature used in laboratory testing is 100 degrees, and they measure the indoor temperature at 50 degrees. Even in hot climates where 100 degrees is the daily high, few spaces are kept at 50 degrees.

A more important aspect of the R-values for insulation is that the laboratories aren't required to test using cold temperatures, which are far more common in our climate than temperatures pushing 100 degrees.

Studies conducted by the Department of Energy’s Oak Ridge National Laboratories show that as outside temperatures drop, the R-value of fiberglass insulation decreases. Using a full-scale climate simulator, Oak Ridge Labs tested loose-fill fiberglass attic insulation rated at R-19 at a variety of temperatures. Once outside temperatures dipped to -8 degrees, the R-19 insulation performed at an R-9.2. What is more surprising was that infrared imaging revealed convective currents inside the fiberglass insulation. Warm air from inside the house would rise through the insulation, lose heat by coming in contact with the cold attic temperatures, and drop back through the insulation, forming a convective loop of constant energy loss.

In contrast, the rigid foam insulation like that used in Enercept SIPs actually performs better in colder temperatures. EPS with a stated R-value of R-3.85 per inch at 75 degrees was tested at R-4.17 per inch at 50 degrees and R-4.4 per inch at 25 degrees. More importantly, because all types of SIPs have solid insulation completely enclosed with wood sheathing, they are not subject to any convective currents like fiberglass insulation.

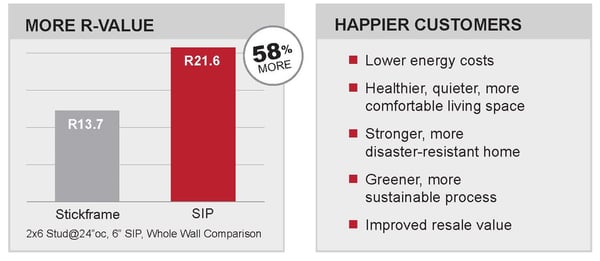

EPS has a stated R-value of R-3.85 per inch at 75 degrees, R-4.17 at per inch at 40 degrees, and R-4.4 per inch at 25 degrees. An Enercept 4.5-inch SIP Panel will outperform a stick and batt 2-by-6 wall with R-19 insulation because of its increased R-values and superior air tightness – especially when the temperature gets colder outside. By stopping airflow with a solid EPS foam core found in SIP’s, you will make your home much more energy efficient and reduce your heating and cooling costs by 50 to 70 percent.

Here at Enercept, we know that to insulate the space between the studs with fiberglass is not the same as insulating an entire wall. We consider the whole wall as a system and understand the importance of insulating the entire wall and not just the area between the framing members.

Fiberglass insulation performs well in controlled laboratory tests, but it is susceptible to air infiltration. When air enters a wall through a crack in the siding or near a window opening, it flows through the fiberglass and reduces its ability to resist thermal flow. Also, moisture causes fiberglass to significantly lose its insulating ability. R-value doesn't account for these problems.

EPS insulation used in Enercept SIPs offers a tighter interface than fiberglass batts by eliminating air infiltration, which is why the use of whole R-value is more accurate in describing thermal performance of the system than the respective R-values of the components. This is just one other consideration that consumers need to make when determining the best insulation system.

Do you want to learn more?