Why are builders committing to fewer housing starts, in spite of strong demand?

According to a Home Builders Institute (HBI) report, the construction industry is facing a shortfall of over 200,000 workers in 2021. Builders cite the difficulty of finding skilled workers among their top concerns, ranking third behind high lumber prices and regulatory burdens.

Some 60% of builders report a worker shortage; subcontractors are also feeling the pinch. Labor represents 30%-40% of the cost of a new home - a figure on the rise due to the higher cost of attracting and retaining skilled labor in a shrinking pool of available workers.

Where did they go?

- During the pandemic, the construction industry lost 975,000 jobs in April 2020 due to lower demand. Many of these skilled craftsmen, part of an aging workforce, have dropped out of the industry.

- Many high schools no longer offer shop classes, and parents often encourage students to pursue a four-year college degree and a white-collar career.

The result is a smaller labor pool. With less labor, projects are taking longer, and builders are turning down work. Builders feel it is better to disappoint a potential customer than make them angry when they can't deliver.

Is it time to rethink you construction business plan?

Is it time to look at other building methods?

Is it time to try SIP construction?

Yes, yes, and YES! Here are seven reasons why:

1. Faster construction—Structural insulated panels combine structural framing, insulation, and sheathing into one step. All Enercept window and door openings are factory built, complete with framing.

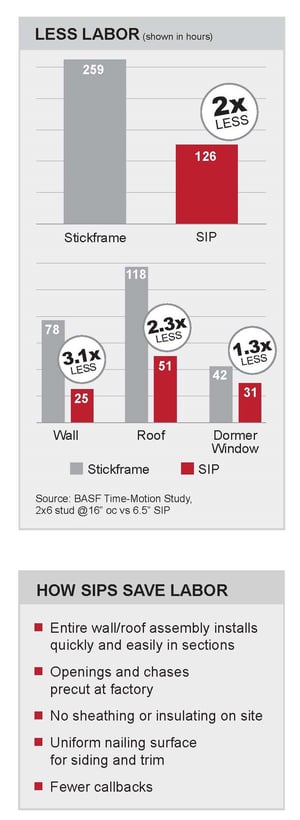

2. Less framing labor—Building with structural insulated panels requires less on-site labor. You can save money, and build more homes each year with fewer employees.

A BASF Corporation time and motion study conducted by the RS Means unit of Reed Construction Data shows that residential builders can reduce their framing labor needs by as much as 55 percent by using structural insulated panels (SIPs) instead of conventional “stick-building” methods.

3. Less job site waste—We've seen examples where the exterior framing waste of an Enercept home can be hauled off in a single 55-gallon container. So, instead of renting a roll-off container, you may be able to remove the waste in the bed of your pick-up.

4. Fewer framing errors—SIPs reduce the margin for framing errors. Each panel is numbered to correspond with a computerized CAD panel blueprint. Panels are built to customer specifications, taking the hassle and guesswork out of design and quality control on-site.

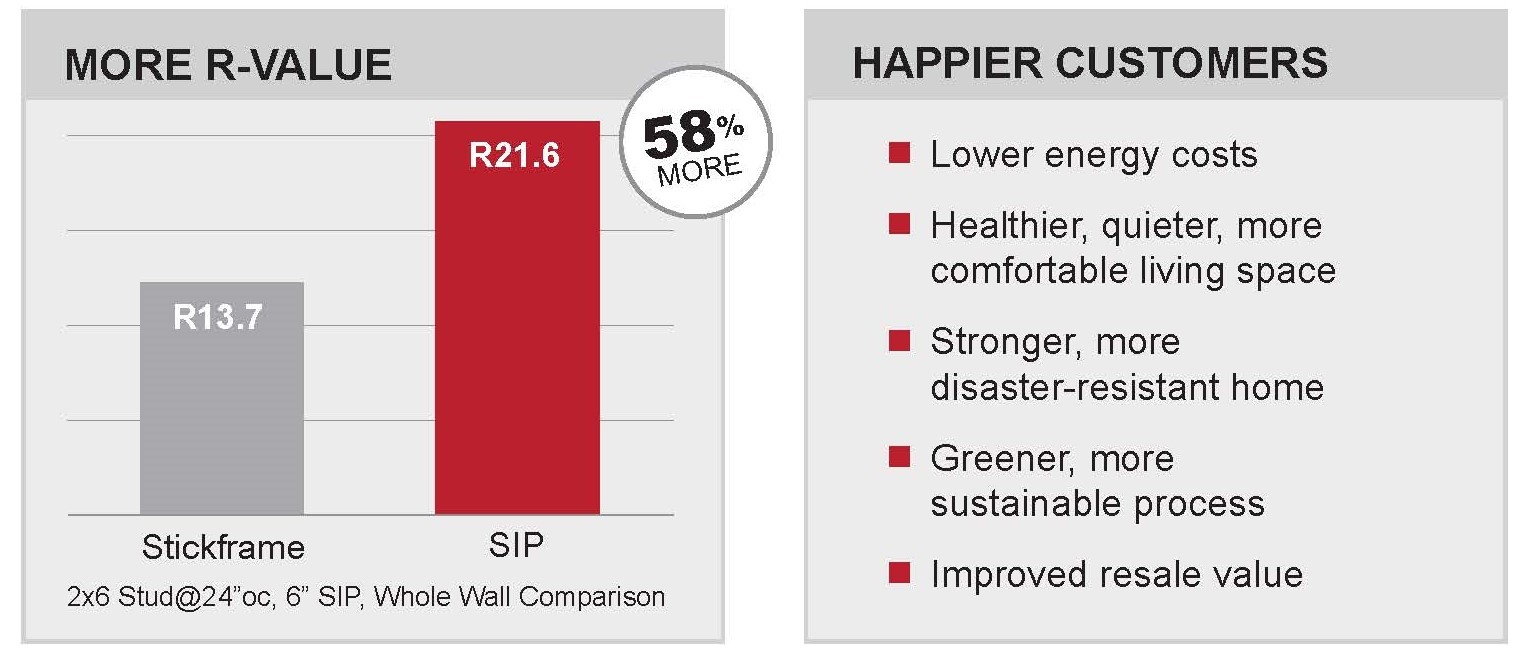

5. Increased demand for green, energy-efficient buildings/homes—SIPs meet this demand. More and more consumers are looking for high-performance building envelopes. Plus, building codes are calling for tighter envelopes.

6. Factory-built SIPs are built inside—This means there is less exposure to the elements during construction - decreasing the risk of rot and mold. SIPs are prefabricated and save on overall construction time.

7. Customer Satisfaction—SIPs offer increased structural stability and accuracy. Not only are the solid building blocks inherently sturdier, but they go up smoother and straighter and result in a structure that is truer to the blueprints. But, the main thing that draws homeowners to SIPs is their superior insulating qualities. A SIP house is insulated better than a framed one, plain and simple.