SIPs, by design, are load-carrying panel products

Mother Nature can sometimes be difficult – high winds, heavy snow, hurricanes, and tornadoes are forces of nature that occur on a regular basis in the United States. That is why building with Enercept Structural Insulated Panels (SIPs) result in a building that can withstand loads three to seven times higher than standard stick construction.

The strength of construction is one of the biggest arguments in favor of panel construction over traditional wood framing. When you hear about panel buildings surviving hurricanes and earthquakes while their traditionally framed neighbors shatter into sticks, you must take notice.

The strength of construction is one of the biggest arguments in favor of panel construction over traditional wood framing. When you hear about panel buildings surviving hurricanes and earthquakes while their traditionally framed neighbors shatter into sticks, you must take notice.

The engineering as to why SIPs are strong is simple: Instead of having the weight of the structure centered on the frame studs, the entire shell can shoulder the load. SIP-built homes also tend to do better during natural disasters like hurricanes and earthquakes because SIP walls resist up to 7,000 pounds per foot, which results in structures that are stronger, straighter and wider.

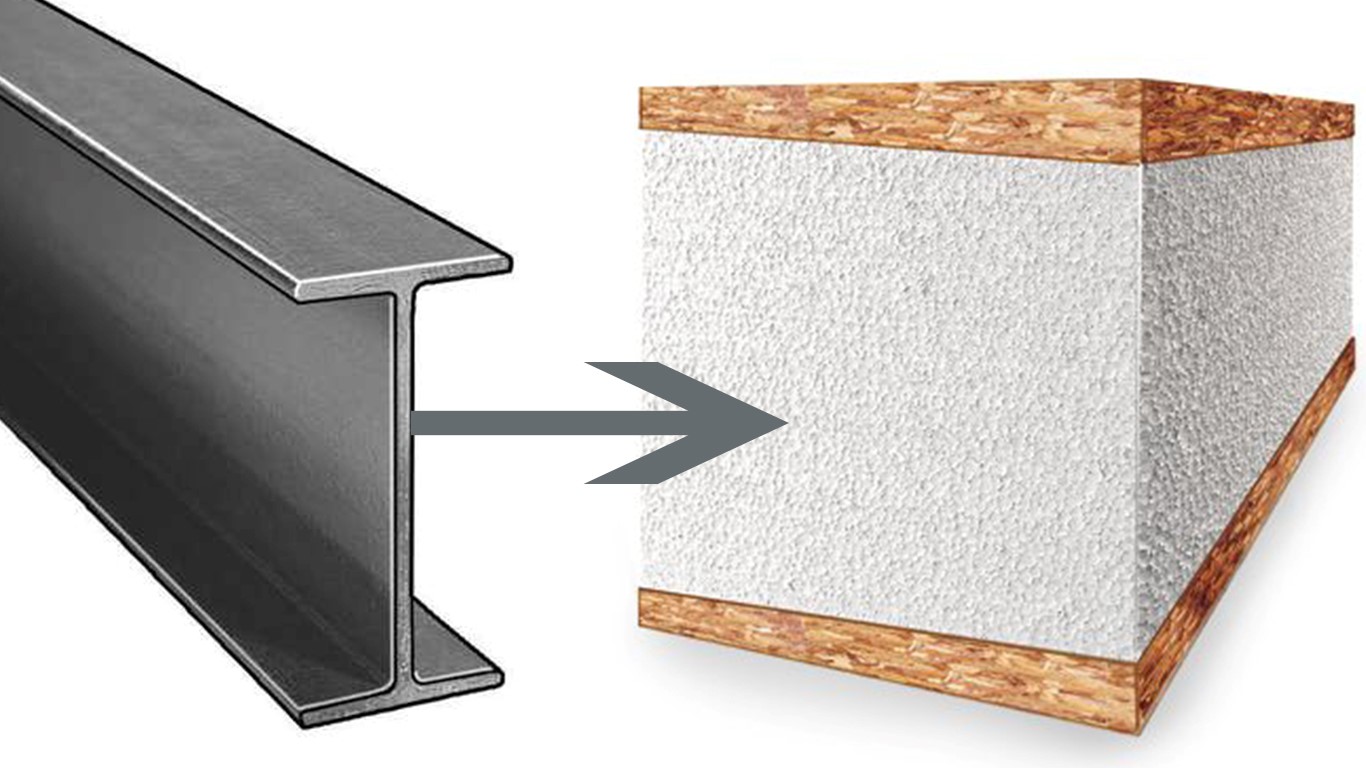

SIPs, by design, are load-carrying panel products consisting of a rigid insulating foam core sandwiched between two structural facings. The materials used to produce these building components can vary greatly in both the structural sheathing and the inner insulation core. Materials commonly used for the panels are orientated strand boards (OSB) grade 3 or plywood combined with a variety of plastic foams, including expanded polystyrene (EPS), extruded polystyrene, urethane, and other similar insulation cores. SIPs structural characteristics are similar to a steel I-bean where the skins ask like the bean flanges, and the rigid core provides the “web” for exceptional stiffness and strength.

Independent scientific tests found that a standard SIP panel wall has over three times as much resistance shear stress as a traditional wall assembly. At a load level that would destroy a conventional wall, a SIP wall has the ability to withstand this force without deforming. This difference is clearly evident in a SIP structure that is exposed to high winds. The absence of creaks and groans is very noticeable. This is also why a SIP building has fewer or no drywall callbacks due to cracking or fastener back-out. Repeated engineering tests show that SIP construction is stronger than a conventional wall and roof framing, and a typical SIP wall panel will withstand vertical compression of over 2,000 pounds per linear foot before structural damage occurs. This means that an eight-foot section of SIP wall would support about four Cadillacs or one Mack truck. No conventionally framed wall could survive this much weight.

Experimental results also showed that SIP panels are better than conventional wood-framing of identical sizes, with respect to flexural, compressive, racking, and cyclic loading. SIP walls have a greater ability to dissipate energy under racking and cyclic loading that the stud wall system – which makes SIP walls preferred by builders in seismic zones.

Bottom line: SIP panels are increasingly the material of choice for walls and roofs to withstand nature’s forces without damage.